What is a Blower Door Test

Blower door test according to DIN EN 13829 / ISO 9972

The blower door measurement allows the air tightness of houses, offices and distribution centres to reliably measure, structural damage and leakage can already be ascertained during the early construction phase. Encountered these defects can be eliminated or reworked in the further stages.

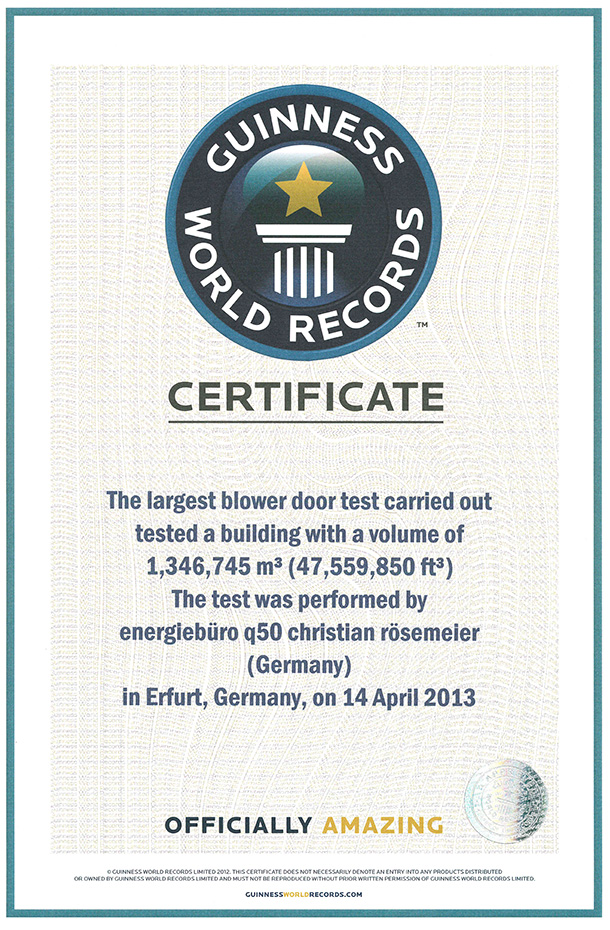

The blower door test checks how many times the air changes per hour under test (test = at 50 pascals, equivalent to a wind pressure of 4-5 Beaufort) in the building takes place. In buildings with a larger air volume 1.500m³ Net volume it is recommended to the q50 value (Hüllflächenbezogener leakage current) to evaluate. The value of q50 is an internationally standardized value allows the comparison of the tightness of the building envelope.

In order to establish this differential pressure in the building called the blower door is used in the doorposts of an outside door. This consists of a customizable aluminum frame which is covered with an airtight nylon tarp. In an opening of a fan sitting Plane with variable speed control, these plans can be extended blowers blower door tests on large buildings with up to 3 Minneapolis Blower Door. Measuring points for determining the internal and external pressure and the pressure drop of the complete measuring setup.

With the blower door test of large buildings or houses a vacuum will be created, the fans "suck" a certain flow out of the building, this corresponds to the volume of leakage current which flows in all flaws from the outside into the building. The ratio of the measured flow and the heated volume of the building is referred to as air exchange rate n (n50 value). This leakage flow from the area of ??the whole building can be calculated now.

Construction/installation of the device

Installation of the blower door in the house or the blower door test in large buildings with a special frame.

When should be measured?

Ideally this should be measured as early as possible in the construction phase, the construction involved all have the chance to eliminate leaks with minimal effort. The actual BlowerDoor acceptance test according to DIN EN 13829 can only take place after the shell of the building to be inspected or part of the building is completed. The Energy Saving Ordinance or prescribed by DGNB measurement must comply with the standard, ie, after completion of the building envelope.

According to DIN EN 13829 there are two "types" of measurement:

The "types" of measurement differ only in the preparation of building or building preparation. It must be distinguished for which the measurement is necessary (eg EnEV = B or DGNB method = method A)

Building tightness test - Type A

- building is subjected in use condition (ready) a leak test

- The energy quality is determined

- Subsequent seals can here be only performed poorly

Building tightness test - Type B

- The building envelope must be completed for the acceptance test according to Energy Saving Ordinance

- The quality of the building envelope is to be investigated

- Intentionally existing openings are closed or sealed